Introduction to Utility Vehicle Battery

Utility vehicle batteries are the powerhouse behind the robust performance of modern utility vehicles (UTVs), playing a pivotal role in both transportation and commercial applications. These batteries provide the essential energy needed to operate UTVs, making them indispensable in various industries, from agriculture and construction to recreational off-roading. Could you please explain what makes a utility vehicle battery so essential?

The term “utility vehicle battery” refers to the energy storage units specifically designed to power utility vehicles. These batteries are engineered to deliver high power output and withstand the rigorous demands of off-road terrains and heavy-duty tasks. Unlike standard automotive batteries, UTV batteries are built to endure frequent deep discharges and rapid recharges, ensuring that the vehicle remains operational in challenging conditions.

In this article, we will delve into the intricate world of utility vehicle batteries, exploring the different types available, such as lead-acid and lithium-ion, and how they compare in terms of performance and cost. We’ll also examine the core components and technological advancements that enhance battery efficiency and reliability. Furthermore, we’ll discuss the benefits and limitations of these batteries, shedding light on their environmental impact and the latest innovations driving the industry forward.

Imagine you’re on an off-road adventure, navigating rugged trails with ease, thanks to the reliable power of your UTV battery. This scenario highlights the importance of understanding and selecting the right battery for your utility vehicle. Whether you’re a business owner relying on UTVs for daily operations or an enthusiast seeking the thrill of off-road exploration, knowing the ins and outs of utility vehicle batteries can significantly enhance your experience.

As we progress through this article, you’ll gain insights into maintenance strategies that optimize battery lifespan, ensuring your UTV is always ready for action. We’ll also provide a comprehensive cost analysis and discuss the environmental considerations associated with different battery types. By the end, you’ll be well-equipped to make informed decisions about the best utility vehicle battery for your needs, paving the way for sustainable and efficient mobility.

Understanding Battery Types for Utility Vehicles

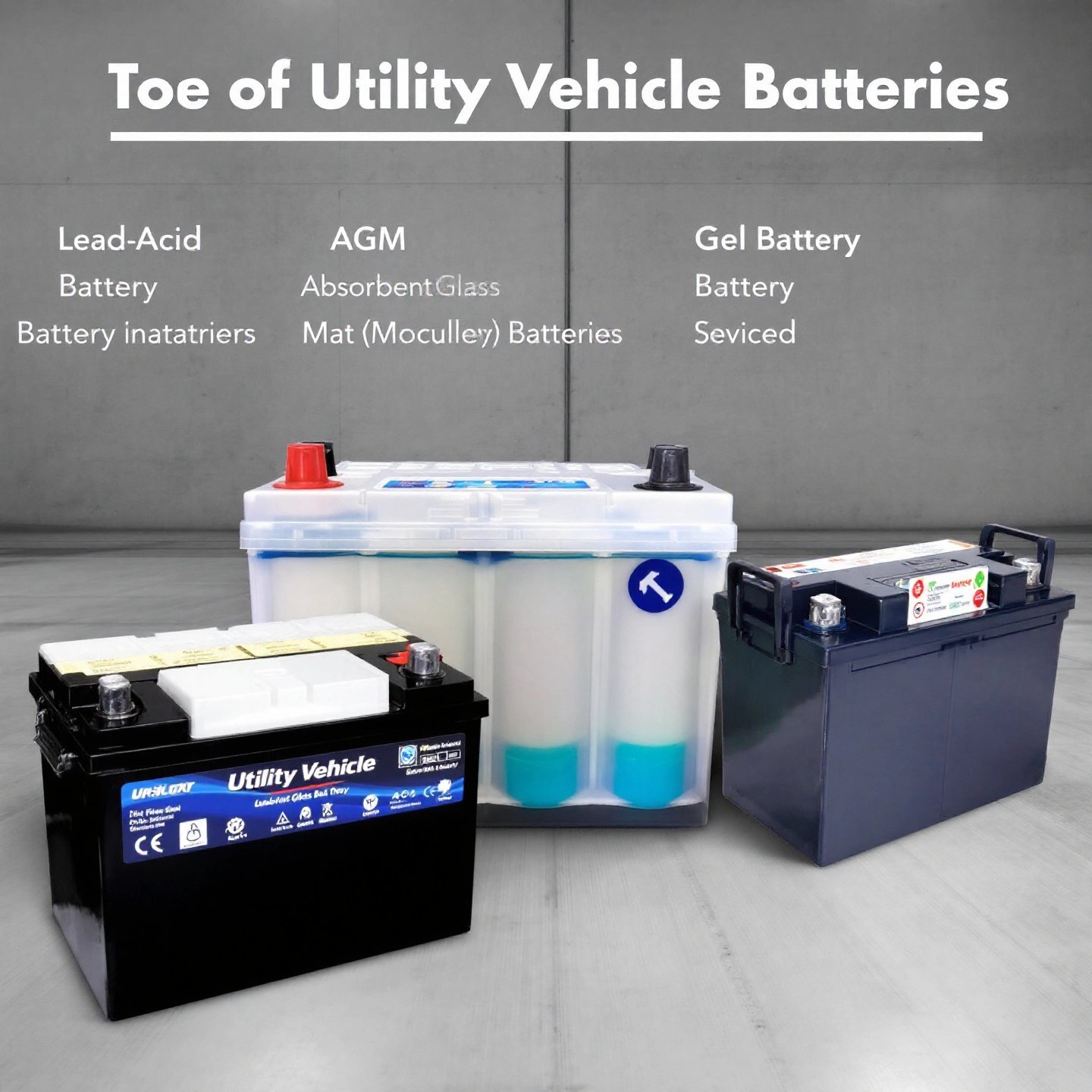

When it comes to powering utility vehicles (UTVs), the choice of battery can significantly impact performance, cost, and reliability. With various UTV battery types available, understanding their unique characteristics is crucial for making an informed decision. Let’s explore the most common types: lead-acid, AGM, gel, and lithium-ion batteries, each offering distinct advantages and trade-offs.

Lead-Acid Batteries

Lead-acid batteries have long been the traditional choice for UTVs, known for their affordability and robust performance. These batteries operate by storing chemical energy between lead plates immersed in a sulfuric acid solution. While they are cost-effective, offering a low price per watt, lead-acid batteries have a lower energy density compared to newer technologies, meaning they are heavier and larger for the same power output. They also require regular maintenance, such as topping up with distilled water, to ensure longevity. However, their widespread availability and reliability make them a popular choice for many UTV applications.

AGM (Absorbed Glass Mat) Batteries

AGM batteries are an evolution of the lead-acid design, incorporating a fiberglass mat to absorb the electrolyte, which makes them spill-proof and more resistant to vibration. This design enhances their durability and reduces maintenance needs, as they do not require watering. AGMs are pricier than standard lead-acid batteries but offer better performance in terms of cycle life and power delivery, making them suitable for users seeking a balance between cost and performance.

Gel Batteries

Gel batteries take the concept of spill-proof design further by using a gel-like electrolyte. This enhances their resistance to leaks, making them perfect for harsh environments that may subject the battery to extreme conditions. Gel batteries offer excellent deep-cycle capabilities, meaning they can be discharged and recharged many times without significant loss of capacity, which is beneficial for UTVs used in demanding applications. However, they come at a higher price point compared to AGM and lead-acid batteries.

Lithium-Ion Batteries

Lithium-ion batteries are at the forefront of battery technology, recognized for their exceptional energy density and lightweight design. They can provide significant power in a compact form, allowing for a more extended range and better performance. Lithium-ion batteries also have a rapid charging time and do not require a cool-down period, unlike lead-acid batteries, which can take longer to charge and need time to cool before reuse. Despite their higher initial cost, lithium-ion batteries offer long-term savings through reduced maintenance and superior efficiency. These attributes make them an attractive option for high-performance UTVs, especially in environments where weight and power are critical factors.

Choosing the right battery type depends on your specific needs, budget, and the conditions in which your UTV operates. Whether you prioritize cost-effectiveness, durability, or cutting-edge performance, understanding these UTV battery types will help you make the best choice for your vehicle.

How Utility Vehicle Batteries Work

Understanding the internal workings of utility vehicle batteries is crucial for appreciating their performance and efficiency. At their core, these batteries are designed to store and release electrical energy through chemical reactions, which power the various components of a utility vehicle. Let’s delve deeper into these core components and the technological advancements that make the technology of modern utility vehicle batteries so effective.

Core Components of Utility Vehicle Batteries

Utility vehicle batteries, such as lead-acid and lithium-ion, have distinct internal structures that define their operation. Lead-acid batteries, for instance, consist of lead plates submerged in an electrolyte solution of sulfuric acid, which facilitates the chemical reactions necessary for energy storage and release. The absorbed glass mat (AGM) variant enhances this capability by using a fiberglass mat to contain the electrolyte, making the battery spill-proof and more durable against vibrations commonly encountered in off-road conditions.

In contrast, lithium-ion batteries utilize a different mechanism, employing lithium compounds as the active material. These batteries are known for their high energy density and lightweight design, which allow for more compact and efficient energy storage. The inside of lithium-ion batteries is made up of cells that contain lithium compounds, a separator to stop short-circuits, and a liquid or gel electrolyte that helps ions move.

Battery Management Systems (BMS)

A critical component of the technology for batteries in modern utility vehicles is the battery management system (BMS). This sophisticated system acts as the battery’s guardian, ensuring safe and efficient operation. The BMS monitors and manages the battery’s state of charge, temperature, and health, preventing issues like overcharging or overheating, which can lead to battery damage or reduced lifespan. For lithium-ion batteries, the BMS is particularly vital, as it balances the charge across individual cells, ensuring uniform performance and longevity.

The BMS also provides real-time data on the battery’s status, allowing users to monitor performance through connected devices, which enhances user convenience and battery management. This feature is especially beneficial in utility vehicles where battery reliability is paramount.

Technological Breakthroughs in Utility Vehicle Battery Technology

Recent advancements have significantly improved the technology of batteries for utility vehicles. Innovations such as fast-charging capabilities, improved energy efficiency, and enhanced safety features have made these batteries more reliable and user-friendly. For instance, lithium-ion batteries now offer rapid charging times and superior energy retention, which are critical for reducing downtime during operations.

Moreover, the integration of smart technologies, such as Bluetooth monitoring and built-in heaters for cold environments, has expanded the functionality of these batteries. These advancements ensure that utility vehicle batteries can perform optimally across a range of conditions, providing consistent power and reliability.

In conclusion, the core components and technological advancements in utility vehicle batteries are pivotal in enhancing their performance and reliability. By understanding these elements, users can better appreciate the capabilities of their utility vehicle batteries, ensuring they choose the right technology for their specific needs and conditions.

Benefits and Limitations of Utility Vehicle Batteries

Utility vehicle batteries are the backbone of modern UTVs, offering various advantages that make them indispensable in both commercial and recreational settings. However, like any technology, they come with their set of limitations. Let’s explore the UTV battery benefits and the challenges they present.

Benefits of Utility Vehicle Batteries

- Performance and Efficiency: Utility vehicle batteries, particularly lithium-ion models, provide high energy density, allowing for extended range and powerful performance. This makes them ideal for demanding tasks and long-distance travel.

- Reliability: Modern UTV batteries are designed to withstand harsh conditions, offering consistent power delivery even in rugged terrains. The integration of battery management systems (BMS) further enhances reliability by safeguarding against overcharging and overheating.

- Environmental Impact: Electric UTVs powered by batteries produce zero emissions during operation, contributing to a cleaner environment compared to traditional gas-powered vehicles. This aligns with global efforts to reduce carbon footprints and promote sustainable practices.

- Cost-Effectiveness: While the initial investment for high-quality batteries like lithium-ion can be significant, their longevity and low maintenance requirements often result in cost savings over time. Reduced fuel and maintenance expenses can offset the higher upfront expense.

Limitations of Utility Vehicle Batteries

- High Initial Cost: Advanced batteries, especially lithium-ion, come with a higher price tag compared to traditional lead-acid options. This expense can be a barrier for budget-conscious buyers.

- Environmental Concerns: Despite their eco-friendly operation, the production and disposal of batteries have environmental implications. The mining of raw materials like lithium and cobalt can lead to habitat destruction and pollution, as highlighted by the Mackinac Center for Public Policy.

- Charging Infrastructure: The availability of charging stations can limit the practicality of electric UTVs, particularly in remote areas. Although home charging is an option, it may not always be convenient for long-distance or frequent use.

- Even with the advancement of technology, extreme temperatures can still affect battery performance. Cold weather, in particular, can reduce battery efficiency and range.

Understanding the limitations of utility vehicle batteries alongside their benefits is crucial for making informed decisions. As technology continues to evolve, many of these challenges are being addressed, paving the way for more efficient and sustainable battery solutions. We will delve into the latest innovations in utility vehicle battery technology in the next section, exploring their potential to transform the industry.

Innovations in Utility Vehicle Battery Technology

Imagine a world where utility vehicles are not just powerful but also smart, efficient, and environmentally friendly. Sounds complex? Not anymore. Recent advancements in battery technology are transforming utility vehicles (UTVs) into high-performance machines that meet the demands of modern users. Let’s delve into the innovative UTV batteries reshaping the industry and the future battery technology trends driving these changes.

Advanced Battery Technologies

One of the most significant innovations in utility vehicle battery technology is the development of solid-state batteries. Unlike traditional lithium-ion batteries, solid-state versions use a solid electrolyte, offering higher energy densities and improved safety. This advancement reduces the risk of overheating and extends the battery’s lifespan, making it ideal for demanding UTV applications.

Moreover, the integration of nanotechnology in battery design is enhancing performance by increasing the surface area for chemical reactions, leading to faster charging times and greater energy efficiency. These tech advances are leading to smaller, lighter, and more powerful batteries, which are vital for improving UTVs’ agility and range.

Smart Battery Management Systems

Battery management systems (BMS) have evolved to become more than just a safety feature. Today’s BMSs are equipped with smart technologies that monitor battery health in real-time, optimize charging cycles, and even predict maintenance needs. Imagine having a system that protects your battery and extends its life by adjusting to your usage patterns.

These smart systems are particularly beneficial in utility vehicles, where reliability and performance are paramount. By ensuring that each cell in a battery pack is charged and discharged evenly, the BMS maximizes the efficiency and longevity of the battery, providing users with a dependable power source for their UTVs.

Emerging Trends in Battery Technology

The future of UTV batteries is bright, with several trends indicating a shift toward more sustainable and efficient solutions. The push for eco-friendly technologies is leading to the adoption of recyclable battery materials and the implementation of closed-loop recycling processes. This approach not only reduces the environmental impact of battery production but also aligns with global sustainability goals.

Furthermore, the integration of artificial intelligence (AI) and machine learning in battery technology is set to revolutionize the industry. AI-driven analytics can predict battery performance under various conditions, allowing for more accurate range estimation and energy management. This technology ensures that utility vehicles are always operating at peak efficiency, regardless of the terrain or task at hand.

As we look to the horizon, it’s clear that innovative UTV batteries and future battery technology are not just enhancing performance but also redefining what utility vehicles can achieve. In the next section, we’ll explore strategies to maintain and optimize these advanced batteries, ensuring they deliver maximum value throughout their lifecycle.

Maintenance and Optimization Strategies for Battery Life

Maintaining your utility vehicle battery is crucial for ensuring long-term performance and reliability. Imagine setting off on an adventure, only to find your UTV won’t start due to a neglected battery. To prevent such scenarios, let’s explore some practical battery maintenance tips and strategies to optimize UTV battery life.

Routine Inspections and Cleaning

Regularly inspecting your battery is essential. Start by checking for any visible signs of damage like cracks or leaks. Use a wire brush to clean the terminals and connections, removing any corrosion that can impede performance. Make sure to securely fasten all cables to prevent electrical inefficiencies; tight connections are crucial.

Proper Charging Practices

Charging your UTV battery correctly can significantly extend its lifespan. Before charging, inspect the battery’s voltage using a multimeter. A reading below 11.8 volts may indicate the need for charging. Use a charger that matches your battery’s specifications, setting the correct voltage and amperage to avoid overcharging or undercharging. For lead-acid batteries, a voltage range of 14.4 to 14.8 volts is typical, while lithium-ion batteries require slightly lower settings.

Consider using a trickle charger for prolonged storage periods. This device maintains the battery at an optimal charge level, preventing discharge. Remember, starting your UTV for a few minutes isn’t enough to charge the battery fully; a trickle charger is more effective for maintaining charge over time.

Temperature Management

Temperature plays a significant role in battery performance. Extreme temperatures can accelerate battery degradation, so it’s important to store your UTV in a climate-controlled environment when possible. If your UTV is exposed to cold weather, consider using a battery heater to maintain optimal performance.

Safety Precautions

Always prioritize safety when handling batteries. Wear gloves and safety glasses to protect against corrosive substances. Ensure the area is well-ventilated during charging to prevent the buildup of explosive gases.

By implementing these maintenance strategies, you can effectively prolong the life of your utility vehicle battery, ensuring it’s always ready for your next adventure. In the following section, we’ll delve into the cost implications and environmental impact of different battery choices, providing insights into sustainable and economical options for UTV owners.

Cost Analysis and Environmental Impact of Utility Vehicle Batteries

When considering the purchase of a utility vehicle battery, it’s essential to look beyond the initial price tag. The total cost of ownership (TCO) encompasses not just the purchase price but also the ongoing expenses related to maintenance, replacement, and energy consumption. Let’s explore how different battery types impact your wallet and the environment over time.

Understanding UTV Battery Cost

At first glance, lead-acid batteries appear to be the most budget-friendly option due to their lower upfront cost. However, they may require more frequent replacements, typically every 3 to 5 years, which can add up over time. In contrast, lithium-ion batteries, despite their higher initial cost, tend to offer a longer lifespan, often exceeding 2,000 charge cycles, as noted by Hawk Carts. This longevity can lead to fewer replacements and potentially lower overall costs in the long run.

Moreover, the efficiency of lithium-ion batteries translates to lower energy costs. Their high energy density allows for more power storage in a smaller footprint, reducing the frequency of recharges and thus the electricity costs associated with charging. AGM and gel batteries fall somewhere in between, offering moderate initial costs and maintenance requirements.

Environmental Impact of Batteries

The environmental impact of batteries is a growing concern, particularly with the increasing focus on sustainability. Traditional lead-acid batteries pose significant environmental challenges due to the toxic materials involved in their production and disposal. Lead and sulfuric acid can cause soil and water contamination if not properly managed.

In contrast, lithium-ion batteries are considered more environmentally friendly. They contain fewer hazardous materials and are more energy-efficient, as highlighted by Ufine Battery. Furthermore, advancements in recycling technologies are improving the recyclability of lithium-ion batteries, thereby reducing their environmental footprint.

AGM and gel batteries also offer environmental benefits over traditional lead-acid batteries due to their sealed design, which reduces the risk of leaks and spills. However, they still contain lead, which necessitates careful disposal and recycling practices.

Balancing Cost and Sustainability

When selecting a utility vehicle battery, it’s crucial to weigh both cost and environmental factors. While lithium-ion batteries may have a higher upfront cost, their efficiency, longevity, and reduced environmental impact often make them a more sustainable choice in the long term. For those prioritizing immediate cost savings, lead-acid batteries remain a viable option, provided that proper disposal and recycling practices are followed to mitigate their environmental impact.

Ultimately, the decision will depend on your specific needs, budget, and commitment to sustainability. As we continue to advance in battery technology and recycling processes, the goal is to minimize the environmental impact while maximizing the economic benefits for utility vehicle owners.

Conclusion

As we conclude our exploration of utility vehicle batteries, it’s clear that these powerhouses are pivotal in shaping the future of mobility and sustainability. Throughout this article, we’ve delved into various aspects of utility vehicle batteries, from understanding different battery types and their core components to examining the benefits and limitations they present. We’ve also explored the innovative strides being made in battery technology, which are set to redefine the capabilities of utility vehicles.

The future of UTV batteries is undeniably promising. Technological advancements, such as solid-state batteries and smart battery management systems, are leading the charge toward more efficient, reliable, and eco-friendly solutions. These innovations not only enhance performance but also align with global sustainability goals by reducing emissions and promoting cleaner energy use. As highlighted by recent trends, the integration of AI and machine learning into battery systems promises to optimize energy management and extend battery life, ensuring that utility vehicles remain efficient and dependable.

Moreover, the industry’s shift toward sustainable battery developments is gaining momentum. Manufacturers are increasingly adopting recyclable materials and closed-loop recycling processes, minimizing the environmental impact of battery production and disposal. This commitment to sustainability is further supported by government incentives and regulations that encourage the adoption of cleaner technologies, fostering a greener future for utility vehicles.

Looking ahead, the utility vehicle industry is poised for significant transformation. As battery technology continues to evolve, we can expect utility vehicles to become even more versatile, capable of tackling a wider range of tasks while maintaining a low environmental footprint. This evolution not only benefits individual users but also contributes to broader environmental conservation efforts.

In conclusion, utility vehicle batteries are more than just a power source; they are a catalyst for innovation and sustainability in the transportation sector. By embracing these advancements, we can drive forward a future where utility vehicles are not only powerful and efficient but also environmentally conscious. As we continue to innovate and adapt, the potential for utility vehicle batteries to revolutionize the industry is boundless, paving the way for a cleaner, more sustainable future.

Frequently Asked Questions

1. What type of battery is best for a utility vehicle?

The best battery type depends on your needs. Lithium-ion batteries offer high energy density and longer lifespan, making them ideal for high-performance UTVs. Lead-acid batteries, while cheaper, require more maintenance and have a shorter lifespan.

2. How can I extend the life of my UTV battery?

Regular maintenance is key. Clean terminals, ensure tight connections, and use a trickle charger during storage. Avoid extreme temperatures and follow proper charging practices to enhance battery longevity.

3. What are the environmental impacts of UTV batteries?

Lithium-ion batteries are more environmentally friendly due to lower toxic material content and better recyclability. Lead-acid batteries pose environmental risks if not disposed of properly.

4. How do battery management systems enhance battery performance?

Battery management systems monitor battery health, optimize charge cycles, and prevent issues like overcharging, thus extending battery life and ensuring reliable performance.

5. Are there any recent innovations in UTV battery technology?

Yes, advancements include solid-state batteries and smart BMS, improving safety, efficiency, and lifespan. AI integration in battery management is also emerging, enhancing performance prediction and energy management.