Introduction to Connecting 3 12V Batteries for a 24V System

Need a 24V power source but only have three 12V batteries? Learning how to connect 3 12V batteries to make 24V offers a cost-effective solution for solar installations, RVs, or marine systems. While using an odd number of batteries isn’t ideal, this setup balances affordability and functionality—perfect for DIY enthusiasts or those repurposing existing equipment. However, it requires careful planning to avoid voltage imbalances and ensure safe operation.

Why choose three batteries instead of two or four? For many users, it’s about maximizing available resources. You might already own one 12V battery and purchase two more to scale up, or space constraints might limit your setup to three units. Common applications include:

- Off-grid solar arrays needing 24V input for inverters

- RV electrical systems requiring stable 24V power

- Marine setups where battery redundancy matters

This hybrid configuration combines parallel and series connections—two batteries linked in parallel to maintain 12V while doubling capacity, then connected in series with a third battery to reach 24V. But challenges like uneven charging and load distribution demand attention. According to JMH Power, mismatched batteries in such setups can reduce efficiency by up to 20% if not properly balanced.

In this guide, you’ll discover:

- Optimal battery types and compatibility checks

- Safety protocols to prevent short circuits

- A step-by-step wiring diagram for 24V output

- Troubleshooting tips for voltage drops

- Solar integration to stabilize performance

Are you prepared to convert your 12V batteries into a dependable 24V system? Let’s start with understanding the right batteries for your setup.

Understanding 12V Battery Types and Configurations

Does battery chemistry matter when building a 24V system? Absolutely. Choosing between lead-acid, lithium-ion (LiFePO4), and AGM batteries impacts performance, longevity, and safety—especially when connecting three units. Let’s break down their key differences:

| Type | Voltage Stability | Cycle Life | Cost |

|---|---|---|---|

| Flooded Lead-Acid | Declines as capacity depletes | 300-500 cycles | $ |

| AGM (Absorbent Glass Mat) | More stable than flooded | 500-800 cycles | $$ |

| Lithium-Ion | Consistent until fully discharged | 3,000-5,000 cycles | $$$ |

Lithium batteries, as noted in Power-Sonic’s analysis, maintain stable voltage under load and last 10x longer than lead-acid. However, their upfront cost is higher. AGM strikes a middle ground—maintenance-free and vibration-resistant, ideal for mobile applications.

Why Identical Batteries Are Non-Negotiable

Mixing battery capacities or ages in a 24V setup is like pairing mismatched tires on a car: one component will wear faster, compromising the whole system. For example:

- A new 100Ah battery paired with an older 80Ah unit will charge/discharge unevenly, stressing both

- Lithium and lead-acid batteries have different charging profiles—combining them risks overcharging or undercharging

As Powmr’s guide emphasizes, all batteries in a series-parallel configuration must share the same chemistry, capacity, and age. Even minor differences in internal resistance can cause imbalance, reducing efficiency by up to 30%.

Why Three Batteries Work (With Caveats)

While two or four batteries simplify symmetrical wiring, three units are feasible through a hybrid setup: two in parallel (+ to +, – to -) to maintain 12V/200Ah (if using 100Ah batteries), then connecting that group in series with a third battery to reach 24V. However:

- The third battery operates solo in series, so it must exactly match the parallel pair’s voltage and capacity

- Regular voltage checks are critical—the series-connected battery discharges faster than the parallel group

Up next: Learn how to wire this configuration safely while avoiding short circuits and overheating risks.

Safety Precautions for Battery Wiring

Have you ever wondered why professionals treat battery wiring like handling live explosives? When working with 12V batteries to create a 24V system, preventing short circuits and chemical hazards isn’t optional—it’s survival. Let’s explore the non-negotiable safety measures that’ll keep you and your batteries intact.

Essential Gear for Safe Battery Handling

- Insulated gloves: Protect against accidental shocks and acid contact (OSHA requires voltage-rated gloves for live circuits)

- Safety goggles: Shield eyes from sparks or battery acid splashes

- Acid-resistant apron: Critical when handling flooded lead-acid batteries

- Fire extinguisher: Class C-rated for electrical fires

Workspace Setup: Your First Line of Defense

- Work in a ventilated area to disperse hydrogen gas (4% concentration becomes explosive)

- Lay down acid-neutralizing mats to contain spills

- Keep a spill kit with baking soda and absorbent pads nearby

- Remove all jewelry to avoid accidental shorting

| Check | Action | Purpose |

|---|---|---|

| Battery terminals | Clean with wire brush | Prevent poor connections |

| Cable insulation | Inspect for cracks | Avoid exposed wires |

| System load | Disconnect entirely | Prevent live wiring accidents |

| Hydrogen levels | Verify ventilation (per OSHA 29CFR1926) | Avoid explosive atmosphere |

The Silent Killers: Hidden Risks in Battery Wiring

- Short circuits: A dropped wrench can weld itself to terminals in milliseconds—always cover terminals with insulating caps when not in use

- Thermal runaway: Overheated lithium batteries can self-ignite—monitor temperatures during first charge cycles

- Acid leaks: Neutralize spills immediately with baking soda to prevent corrosion

Pro Tip: Use only insulated tools with rubberized grips, and double-check that all loads are disconnected before touching any wires. Now that your workspace is secured, let’s dive into the actual wiring process.

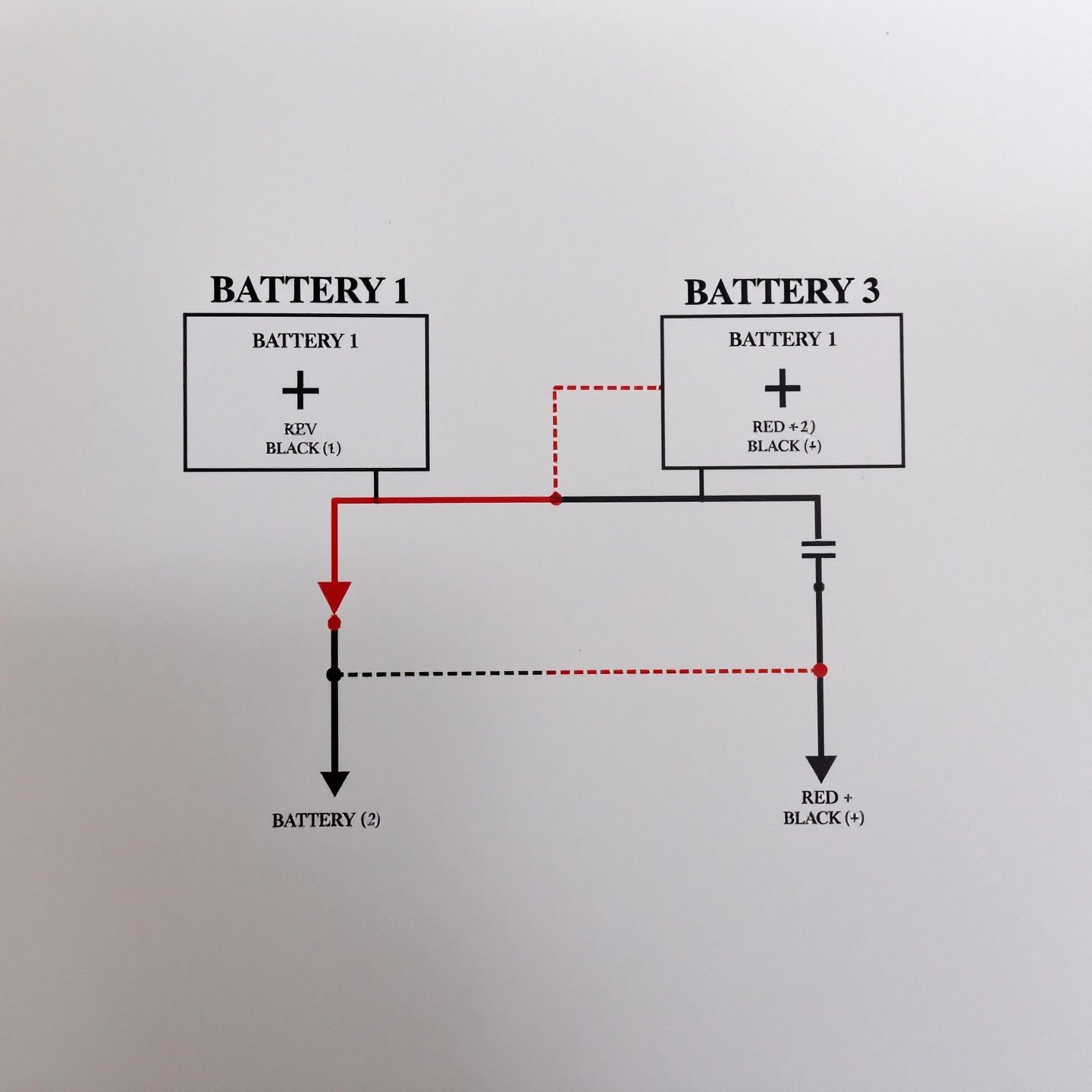

Step-by-Step Wiring Guide: 2 Parallel + 1 Series

Are you prepared to connect your three 12V batteries to a functional 24V system? This hybrid configuration combines parallel and series connections to achieve double the voltage while maximizing capacity. Here’s how to execute it safely and efficiently.

Tools You’ll Need

- Insulated 10mm wrench set

- 4-gauge battery cables (red/positive and black/negative)

- Digital multimeter (testing guide)

- Terminal cleaning brush

- Heat-shrink tubing for connections

Wiring Process Explained

- Connect Two Batteries in Parallel

- Link Battery A’s positive (+) terminal to Battery B’s positive using a red cable

- Connect Battery A’s negative (-) to Battery B’s negative with a black cable

- Result: 12V system with combined capacity (e.g., two 100Ah batteries = 200Ah)

- Add the Third Battery in Series

- Attach a red cable from the parallel group’s positive terminal to Battery C’s positive

- Connect Battery C’s negative terminal to your system’s 24V load/device

- The parallel group’s negative becomes the system’s overall negative

| Battery | Connection | Terminal Voltage |

|---|---|---|

| A & B (Parallel) | + to +, – to – | 12V combined |

| C (Series) | + to parallel group’s + | 12V added |

| Total System | A/B (-) to C (+) | 24V output |

Testing & Validation

- Voltage Verification

- Set multimeter to DC voltage (20V+ range)

- Touch red probe to system’s final positive (Battery C +)

- Touch black probe to system’s final negative (Parallel group -)

- Reading should be 24-25.2V (fully charged)

Critical Warning: Mismatched Batteries

Using dissimilar batteries in this setup is like mixing oil and water. Even a 5% capacity difference can cause:

- Imbalanced Charging: The series-connected battery charges/discharges faster

- Reduced Lifespan: Capacity variance strains all units

- Thermal Risks: Overworked batteries may overheat

Pro Tip: Label all batteries with purchase dates and cycle counts. Replace all three if one fails to maintain uniformity.

Now that your 24V system is live, let’s explore how to manage voltage fluctuations and optimize load distribution for long-term reliability.

Voltage and Load Management

When combining three 12V batteries into a 24V system, understanding how connections affect capacity and voltage is crucial. Let’s break down the math and practical implications of your hybrid setup.

Amp-Hour Calculations: Parallel vs. Series Effects

In a 2P+1S configuration (two batteries in parallel, one in series):

- Parallel connections increase capacity: Two 100Ah batteries → 200Ah at 12V

- Series connections increase voltage: 12V + 12V = 24V

| Configuration | Voltage | Capacity (Ah) | Total Energy (Wh)* |

|---|---|---|---|

| Single 12V Battery | 12V | 100Ah | 200 |

| Two in Parallel | 12V | 200Ah | 2,400 |

| Three in 2P+1S | 24V | 100Ah | 2,400Wh |

*Calculated using Wh = Ah × Voltage

While three batteries store 3,600Wh of energy individually, the 2P+1S configuration only delivers 2,400Wh due to the series-linked battery limiting capacity. This trade-off makes four-battery systems (2S2P) more efficient but less space-friendly.

Managing Mixed Voltage Loads

Most 24V systems still need to power 12V devices like lights or USB ports. Here’s how to balance both:

| Device Voltage | Solution | Example Products |

|---|---|---|

| 24V | Direct connection | 24V inverters, industrial motors |

| 12V | DC-DC converter (24V→12V) | RV lighting, car stereos |

| 5V | USB adapters | Phones, tablets |

Pro Tip: A 24V pure sine wave inverter paired with a 24V→12V converter lets you safely run both high-power appliances (like microwaves) and low-voltage accessories simultaneously.

Why Current Matters

Higher voltage reduces current flow for the same power output. For example:

- A 1,200W device at 12V draws 100A (1,200W ÷ 12V)

- The same device at 24V draws 50A (1,200W ÷ 24V)

This halved current means thinner wires and less energy loss as heat—a key advantage of 24V systems for long-distance setups like solar arrays.

Next Up: Learn how to troubleshoot common issues like uneven charging and voltage drops in your three-battery system.

Troubleshooting Common Issues

Why does your 24V battery system show voltage fluctuations or uneven performance? Three-battery configurations are particularly prone to imbalances due to asymmetrical wiring. Let’s diagnose common issues and implement practical fixes to keep your system running smoothly.

Top Challenges in 3-Battery 24V Systems

| Problem | Cause | Solution |

|---|---|---|

| Uneven charging | Mismatched internal resistance or capacity | Install a battery balancer |

| Voltage drops under load | Loose/corroded terminals or undersized cables | Clean connections; upgrade to 4AWG cables |

| Overheating batteries | Excessive current draw or short circuits | Add a 50A circuit breaker |

| Reduced capacity | Aged batteries with sulfation | Replace all three batteries |

Case Study: The 0.5V Imbalance Mystery

As reported in a 2022 Stack Exchange case, two new 12V batteries showed a 0.5V difference during charging despite identical specs. The culprit? Variations in internal resistance from factory defects. The fix involved:

- Disconnecting and parallel-charging both batteries overnight

- Installing a Victron battery balancer to maintain equilibrium

- Replacing one battery after 3 failed balancing attempts

When to Use a Battery Balancer

These devices automatically redirect current between batteries to correct voltage deviations. For three-battery systems:

- Connect one balancer between the series-linked battery and the parallel pair

- Set activation threshold to 0.1V difference (per Victron’s guidelines)

- Monitor via LED indicators: orange for minor imbalance, red for critical (>0.2V)

Preventative Maintenance Checklist

- Weekly: Test individual battery voltages with a multimeter

- Monthly: Inspect terminals for corrosion (clean with baking soda solution)

- Annually: Conduct capacity tests using a load tester

Pro Tip: Solar charging systems inherently reduce imbalance risks by providing steady voltage—a perfect segue to our next section on renewable energy integration.

Enhancing Your System with Solar Panels

Struggling to keep your three-battery 24V system balanced? Solar charging isn’t just eco-friendly—it’s a practical solution for maintaining voltage stability. When paired with a hybrid battery configuration, solar panels provide consistent energy flow, reducing the strain on individual batteries and preventing the imbalance issues common in asymmetrical setups.

Why Solar Works for Three-Battery Systems

Solar charging addresses two critical challenges in 24V systems:

- Balanced Charging: MPPT charge controllers distribute energy evenly, compensating for differences in battery wear

- Continuous Maintenance: Even on cloudy days, trickle charging prevents deep discharges that accelerate aging

| Panel Type | Power Output | Ideal Use | Key Feature |

|---|---|---|---|

| 100W Monocrystalline | 100W @ 18V | Small RVs, backup power | Lightweight (15 lbs) |

| 200W Bifacial | 200W @ 36V | 24V systems, off-grid cabins | 30% rear-side gain |

| 500W Polycrystalline | 500W @ 48V | Whole-home systems | High-efficiency junction box |

Optimizing Solar for 24V Battery Banks

For three-battery setups, we recommend:

- 200W Solar Kits: Perfectly matched to 24V systems, these kits include MPPT controllers that automatically adjust voltage to prevent overcharging

- Bifacial Panels: Capture reflected light (ideal for marine/RV installations), delivering up to 30% more energy

- Modular Design: Start with one panel and expand as needed—no system overhaul required

For reliable solar integration, explore Renewable Energy Nexus’s range of panels, including weather-resistant models tested in extreme temperatures (-40°F to 185°F). Their 200W kit powers typical 24V loads like:

- RV air conditioners (1,200-1,500W)

- 24V trolling motors

- Off-grid water pumps

Pro Tip: Pair solar panels with a battery balancer to automatically equalize charge across all three batteries, extending their lifespan by up to 40%.

Conclusion

Building a reliable 24V system with three 12V batteries requires attention to detail—but the payoff in cost savings and flexible power access makes it worthwhile. Let’s recap the essentials for maintaining 24V battery systems:

- Battery Uniformity: Always use identical batteries in age, capacity, and chemistry to prevent imbalance

- Connection Integrity: Inspect terminals monthly for corrosion and tighten connections to 8-10 Nm torque

- Voltage Monitoring: Test system voltage weekly with a multimeter (24.0-25.2V indicates full charge)

For eco-friendly battery setups, solar integration isn’t just an upgrade—it’s a game-changer. Solar panels paired with MPPT charge controllers:

- Reduce strain on individual batteries through consistent charging

- Extend battery lifespan by up to 40% (per Lifepo4 studies)

- Cut energy costs by 60-90% compared to grid-dependent systems

Pro Tip: Pair your system with Renewable Energy Nexus’s 200W solar kits featuring bifacial panels. These units deliver 30% more output from reflected light—ideal for RVs or marine installations where space is limited.

Ready to future-proof your power solution? Sustainable energy starts with smart choices. For expert-curated solar solutions that harmonize with your 24V battery bank, explore Renewable Energy Nexus’s solar panel range today.

FAQs: Connecting 3 12V Batteries for 24V Systems

1. Can I use different types of 12V batteries in a 24V setup?

No. Mixing battery chemistries (e.g., lithium and lead-acid) or capacities causes dangerous imbalances. Identical age, brand, and specifications are critical for safe operation.

2. How do I prevent uneven charging in a 3-battery 24V system?

Use a battery balancer between the series-connected battery and parallel pair. Regularly check individual voltages with a multimeter, and replace all batteries if one shows significant capacity loss.

3. What gauge wire is safe for connecting 12V batteries to 24V?

4-gauge cables are recommended for most setups handling up to 50A. For high-power systems (e.g., 100A+ inverters), upgrade to 2/0 AWG to minimize heat and voltage drop.

4. Can solar panels charge a 24V system made from three 12V batteries?

Yes. Pair a 200W+ solar kit with an MPPT charge controller, like Renewable Energy Nexus’s bifacial models, which automatically balance charging across asymmetrical battery configurations.

5. Why does my 24V system read 26V after charging?

This is normal. Fully charged 12V batteries measure ~13.2V each. Three in a 2P+1S configuration will show 26.4V (13.2V + 13.2V), which stabilizes to 24V under load.