Introduction to Generator to Inverter

In an era where energy efficiency and sustainability are paramount, transitioning from traditional generators to inverter technology offers significant advantages for both residential and commercial applications. But what makes this shift so compelling? Let’s explore the key benefits that inverter technology brings to the table.

Traditional generators, while effective, often run at a constant speed, leading to higher fuel consumption and increased emissions. In contrast, inverter generators adjust their engine speed to match the required load, making them more fuel-efficient and environmentally friendly. This ability to modulate power output reduces fuel usage and minimizes noise, making inverter generators ideal for both home use and outdoor activities like camping or tailgating.

Moreover, inverter generators produce cleaner power. They convert direct current (DC) to alternating current (AC) through a more refined process, resulting in a stable and consistent power output. This method is particularly beneficial for sensitive electronics and medical devices that require a steady power supply without fluctuations.

As we delve deeper into this article, we will cover various aspects of inverter technology, including understanding power ratings, safe setup and grounding practices, and even how to convert a traditional generator to an inverter. By the end, you’ll have a comprehensive understanding of how to harness the full potential of inverter technology for your energy needs. Whether you’re looking to reduce your carbon footprint or simply want a more reliable power source, transitioning from a generator to an inverter could be the right move for you.

Understanding Power Ratings for Inverter Generators

Choosing the right inverter generator can feel overwhelming, especially with the myriad of options available. However, understanding the power ratings—particularly in the 2 to 3 kilowatt range—can simplify your decision-making process. These ratings are crucial as they determine the generator’s capacity to meet your energy needs.

What Does Power Rating Mean?

Power rating, expressed in watts, indicates the maximum continuous power a generator can supply. For inverter generators, this often includes two ratings: rated (running) watts and surge (starting) watts. Rated watts refer to the power output that the generator can sustain over time, while surge watts account for the extra power needed to start devices like refrigerators or air conditioners.

Applications for 2 to 3 Kilowatt Generators

Inverter generators with power ratings between 2,000 and 3,000 watts are ideal for various applications. They are perfect for running essential household appliances during a power outage, such as refrigerators, lights, and small air conditioning units. Additionally, these generators are popular for outdoor activities, providing reliable power for camping trips or tailgating events.

Evaluating Your Power Needs

To select the right generator, start by listing all the devices you plan to power and their wattage requirements. Add these values to get a total wattage, ensuring that you account for both running and surge needs. For instance, a refrigerator might require 700 running watts but 1,200 surge watts to start. By understanding your total power demand, you can choose an inverter generator that prevents overloading, ensuring both safety and efficiency.

Remember, selecting a generator with a slightly higher capacity than your calculated needs can provide a buffer for unexpected power surges. This approach protects your equipment and extends the lifespan of your generator.

Next, we’ll explore how to safely set up and ground your inverter generator, ensuring optimal performance and safety in all environments.

Setting Up and Grounding Inverter Generators

When it comes to using inverter generators safely, proper setup and grounding are crucial. But if you’re wondering, “How do I ensure my generator is safe?” you’re not alone. Understanding the grounding process can protect you from potential electrical hazards and ensure optimal performance.

Why Grounding is Essential

Grounding an inverter generator is a safety measure that helps direct any fault current away from the generator, reducing the risk of electric shock. Connecting the generator’s frame to a grounding electrode, like a ground rod, achieves this. According to Mighty Generators, this process is vital for ensuring that the generator’s metal parts, which are not meant to carry electric current, remain safe.

Steps to Ground Your Inverter Generator

- Gather Necessary Tools: Start with a copper grounding rod and wire strippers. These tools are essential for creating a stable electrical circuit.

- Install the Grounding Rod: Drive the copper rod into the ground at least 8 feet deep to reach moist soil. This step ensures a good electrical connection.

- Connect the Generator: Use wire strippers to remove insulation from the copper wire ends. Securely attach one end to the grounding rod and the other to the generator’s grounding bolt.

By following these steps, you ensure a safe path for any excess electricity, safeguarding both the generator and its users.

Additional Safety Measures

Proper ventilation is another critical aspect of inverter generator safety. Generators should be operated outside, at least 25 feet away from buildings, windows, and doors, to prevent carbon monoxide buildup. As highlighted by Travelers, using a carbon monoxide detector can alert you to potential dangers, ensuring a safer environment.

Moreover, ensure that nothing is placed on or near the generator to allow for proper airflow and prevent overheating. Regularly inspect your grounding system for signs of wear or damage, and test it periodically using a multimeter to confirm a good earth connection.

Grounding your inverter generator not only enhances safety but also boosts its efficiency and longevity. By taking these precautions, you’ll be better prepared to handle any power needs safely and effectively. As we continue, we’ll delve into best practices for breaking in your new inverter generator to maximize its performance.

Best Practices for Breaking In Your Unit

Imagine purchasing a brand-new inverter generator, only to have it underperform or, worse, fail prematurely. Sounds like a nightmare, right? Properly breaking in your inverter generator is crucial to ensure its longevity and optimal performance. This process involves a few simple yet vital steps that can significantly extend the lifespan of your unit.

Why Break In Your Generator?

The break-in process is essential because it helps in properly seating the engine’s piston rings and ensures that all internal components are well-lubricated. According to Generator Mart, without a proper break-in, your generator’s engine may suffer from a dry start, which can lead to severe damage over time. Additionally, this process helps in removing any metal shavings left from manufacturing, which can cause internal damage if not cleared.

Step-by-Step Break-In Guide

- Initial Lubrication: Before starting the generator, remove the spark plug and add a few drops of oil conditioner. Pull the starter cord slowly—about 5–10 times— to lubricate the pistons without starting the engine. Reinstall the spark plug once done.

- Oil and Fuel Filling: Fill the crankcase with oil conditioner and then add the recommended oil. Ensure that the oil and fuel compartments are filled according to your user manual’s specifications.

- First Run: Start the generator and let it run without any load for about an hour. This step helps in the initial settling of the engine components. After this period, turn off the generator, drain the oil, and refill it. At this stage, there is no need to replace the fuel.

- Loaded Run: After the initial no-load run, operate the generator at a load of at least 75% capacity for 50 to 100 hours. This procedure ensures the engine components are properly seated under working conditions. During this period, regularly check and change the oil as needed.

Maintaining Your Generator

Regular maintenance is key to keeping your inverter generator in top condition. As advised by Outbax, changing the oil after the first 24 hours of use and then every six months is crucial. Additionally, keeping the air filter clean and the spark plug in excellent condition will ensure your generator runs smoothly. Remember, a well-maintained generator performs better and lasts longer.

By following these steps, you’ll ensure that your inverter generator operates efficiently and reliably for years to come. Next, we’ll explore how to convert a traditional generator to an inverter, providing cleaner and more efficient power solutions.

Converting a Traditional Generator for Cleaner Power

Have you ever wondered if you could transform your traditional generator into a more efficient and cleaner power source? Converting a generator to an inverter might sound complex, but it’s a feasible project with the right tools and guidance. This section will walk you through the process, highlight potential challenges, and show how consulting resources like those from Renewable Energy Nexus can ease your conversion journey.

Understanding the Conversion Process

At its core, converting a generator to an inverter involves integrating an inverter component that modifies the power output. Traditional generators produce direct current (DC), which needs to be converted to alternating current (AC) to power most household appliances. An inverter does this by taking the DC output and converting it into a stable AC output, suitable for sensitive electronics.

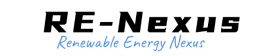

Steps to Convert Your Generator

- Select the Right Inverter: Choose a pure sine wave inverter for the best compatibility with sensitive electronics. These inverters provide a cleaner power output compared to modified sine wave inverters.

- Acquire a Generator Conversion Kit: These kits typically include an inverter, necessary wiring, and installation instructions. Ensure the kit matches your generator’s specifications to avoid compatibility issues.

- Install the Inverter: Follow the kit’s instructions to connect the inverter to your generator. This step usually involves wiring the inverter to the generator’s output terminals and securing it in place.

- Test the Setup: Once installed, test the system by powering various appliances to ensure the inverter is functioning correctly and providing stable output.

Challenges and Considerations

Converting a generator to an inverter is not without its challenges. Compatibility issues can arise if the inverter is not correctly matched to the generator’s output. Additionally, the installation process can be technical, requiring a solid understanding of electrical systems. Consulting with professionals or resources like those from Renewable Energy Nexus can provide valuable guidance and support, ensuring a successful conversion.

Another critical aspect is ensuring the system is grounded properly to prevent electrical hazards. As with any electrical project, safety should be a top priority, and professional advice can help mitigate risks.

Converting a traditional generator to an inverter can significantly enhance its efficiency and reduce emissions, making it a worthwhile investment for those seeking cleaner power solutions. As we continue, we’ll explore how adding inverter modules can further optimize efficiency and scalability.

Adding Inverter Modules for Greater Efficiency

Imagine transforming your existing generator into a powerhouse of efficiency and scalability. It sounds intriguing, doesn’t it? By adding inverter modules to your generator, you can achieve just that. This process enhances the generator’s performance and offers flexibility in managing power loads. Let’s delve into how you can add inverter modules to a generator and the benefits they bring.

Why Add Inverter Modules?

Inverter modules are designed to convert direct current (DC) to alternating current (AC) with high efficiency. By integrating these modules into your generator setup, you can improve the overall conversion efficiency, often reaching up to 96% as noted by CE+T America. The result means less energy loss and lower operational costs, which is particularly beneficial for businesses looking to optimize their power usage.

Steps to Add Inverter Modules

- Assess Current Setup: Begin by evaluating your generator’s existing configuration and power requirements. This assessment will help determine the number and type of inverter modules needed.

- Select the Right Modules: Choose modular inverter systems that are compatible with your generator’s output. Brands like CE+T America offer hot-swappable modules, which allow for easy installation and future scalability without downtime.

- Install the Modules: Follow the manufacturer’s guidelines for installation. This step typically involves connecting the inverter modules to the generator’s output terminals and ensuring all connections are secure.

- Test and Monitor: Once installed, test the system to ensure it operates smoothly. Utilize monitoring tools to track performance and make adjustments as necessary.

Comparing Inverter Module Brands

When considering inverter modules, it’s essential to compare different brands to find the most cost-effective solution. For instance, CE+T America’s modular systems offer features like zero downtime and direct grid supply loading, which can significantly reduce energy losses. Evaluating these features against your specific needs will help you make an informed decision.

By adding inverter modules to your generator, you’ll enhance efficiency and gain the flexibility to scale your power system as your needs grow. This approach offers a sustainable solution to meet increasing energy demands while minimizing environmental impact.

In the next section, we’ll explore how integrating batteries can further stabilize your energy storage, providing consistent power even during outages.

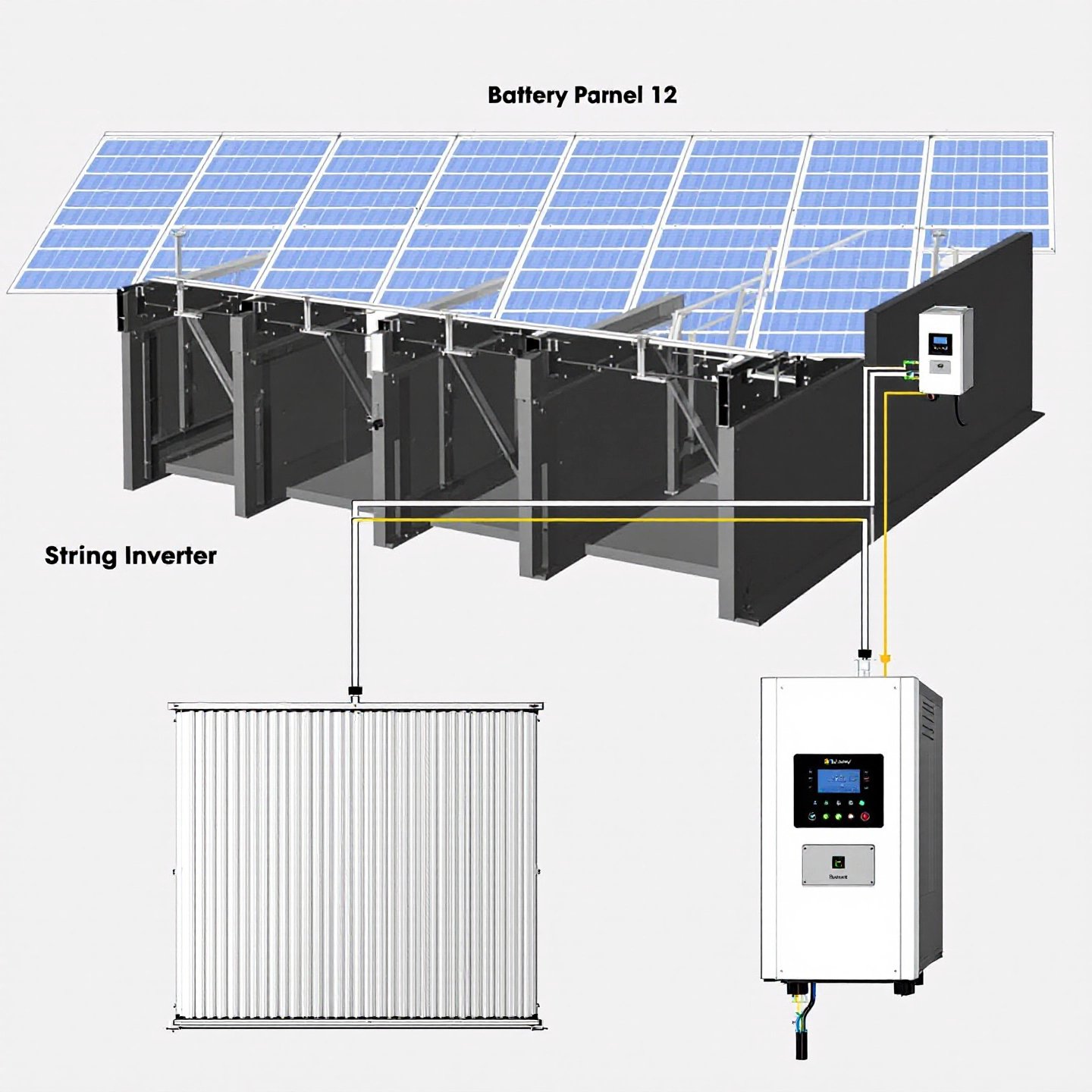

Integrating Batteries for Stable Energy Storage

Imagine a power setup that never leaves you in the dark, even during outages. Sounds complex? It’s simpler than you think with a generator-to-battery-to-inverter system. This configuration ensures a consistent power supply by storing energy in batteries, which can be accessed during peak demands or when the generator is off.

How Does the Setup Work?

The generator-to-battery-to-inverter setup is designed to maximize energy efficiency and reliability. Here’s how it functions:

- Generator: Produces electricity, which is either used immediately or stored in batteries.

- Batteries: Act as energy reservoirs, storing excess power generated. They are crucial for maintaining a steady power supply during generator downtime or when demand exceeds generation.

- Inverter: Converts the DC power stored in batteries to AC power, suitable for household appliances.

This system is particularly beneficial for remote locations or areas with unreliable grid power, ensuring that essential devices remain operational.

Choosing the Right Battery Capacity

Battery capacity is critical in this setup. It determines how long you can rely on stored energy. According to PV Education, the battery’s state of charge (SOC) and depth of discharge (DOD) are key factors. For instance, a higher SOC means more stored energy, while a lower DOD extends battery life by preventing deep discharges.

When selecting batteries, consider your power needs and usage patterns. Lithium-ion batteries are popular for their high efficiency and longer lifespan, though they come at a higher cost. Lead-acid batteries are more affordable but require regular maintenance.

Effective Charging Strategies

Efficient charging is essential to maintain battery health and ensure reliable power. Implementing a charge controller can optimize the charging process by regulating voltage and current, preventing overcharging or deep discharge.

Moreover, integrating solar panels from Renewable Energy Nexus can enhance this setup. Solar panels provide a renewable energy source to charge batteries, reducing reliance on generators and lowering operational expenses.

Usage Scenarios and Benefits

This setup is ideal for various applications, from powering off-grid cabins to supplementing home energy needs during blackouts. It offers the flexibility to manage energy resources efficiently, ensuring that power is available when needed most.

By integrating batteries into your power system, you gain a robust solution that enhances energy stability and reduces environmental impact. This approach not only promotes a sustainable lifestyle but also offers comfort in knowing that power is always available.

As we move forward, we’ll discuss how to connect your inverter generator safely to household circuits, ensuring compliance with safety standards and enhancing your power system’s reliability.

Connecting Your Generator to Household Circuits Safely

Imagine a storm hits, and your home loses power. Your inverter generator is ready, but how do you connect it safely to power your house? Sounds daunting? It’s simpler than you might think. With the right setup, you can ensure a seamless transition to generator power, keeping your home running smoothly during an outage.

The Role of a Transfer Switch

A transfer switch is essential for safely connecting an inverter generator to your home’s circuits. This device allows you to switch from utility power to generator power without risking backfeeding, which can be dangerous for utility workers and your electrical system. According to Yoder Electric, a transfer switch isolates your generator from the grid, ensuring that power flows only to the circuits you choose, thereby preventing potential hazards.

Steps to Connect Your Inverter Generator

- Select the Right Transfer Switch: Choose between a manual or automatic transfer switch based on your needs. Manual switches are more affordable and straightforward, while automatic switches offer seamless transitions without manual intervention.

- Professional Installation: Hire a licensed electrician to install the transfer switch. This procedure ensures compliance with local electrical codes and safe operation. The electrician will connect the switch to your electrical panel, allowing you to select which circuits to power during an outage.

- Test the System: Once installed, test the transfer switch by simulating a power outage. Start your generator and switch the transfer switch to generator power. Verify that the selected circuits receive power without any issues.

Considerations for Safe Operation

Proper installation and operation of your inverter generator setup are crucial for safety and efficiency. Here are some additional tips:

- Maintain Load Limits: Ensure that the total wattage of the circuits you power does not exceed the generator’s capacity. Overloading can damage the generator and connected devices.

- Regular Maintenance: Both the generator and transfer switch require regular maintenance. Follow the manufacturer’s guidelines for servicing to ensure reliable performance.

- Weather Protection: Install weatherproof enclosures on your transfer switch or generator inlet box if they are located outdoors to protect them from the elements.

By following these guidelines, you can connect your inverter generator to your home safely and efficiently, ensuring that you have a reliable power source during emergencies. As we conclude, we’ll explore specialized applications and fuel options, including converting inverter generators to propane for cleaner emissions and longer runtime.

Exploring Specialized Applications and Fuel Options

Imagine transforming your inverter generator into a cleaner, more efficient power source by converting it to run on propane. This sounds quite innovative, doesn’t it? This modification reduces emissions and extends the runtime of your generator, making it a compelling choice for eco-conscious users and those seeking reliable power solutions.

Benefits of Converting to Propane

Converting an inverter generator to propane offers several advantages. Propane burns cleaner than gasoline, resulting in fewer emissions and a smaller carbon footprint. According to Grenergy, propane-fueled generators produce less carbon buildup, which can extend engine life and reduce maintenance needs. Additionally, propane is often more readily available during natural disasters, making it a reliable fuel source when gasoline supplies are limited.

Steps for Conversion

- Choose a Conversion Kit: Select a high-quality conversion kit designed for your specific generator model. These kits typically include all necessary components, such as hoses, fittings, and regulators, to facilitate the conversion process.

- Installation: Follow the kit’s instructions carefully to install the components. This step usually involves attaching a propane regulator to the generator’s carburetor and connecting it to a propane tank via the provided hoses.

- Testing: After installation, test the generator to ensure it switches smoothly to propane. Verify that the generator runs efficiently and that there are no leaks in the connections.

Specialized Applications and Safety Considerations

Propane conversion is particularly beneficial for specialized applications, such as powering remote cabins or RVs where access to gasoline might be limited. It’s also ideal for use in environmentally sensitive areas where minimizing emissions is crucial.

However, safety is paramount when modifying fuel systems. Ensure all connections are secure and leak-free to prevent propane leaks, which can be hazardous. Regularly inspect hoses and fittings for wear and replace them as needed. It’s also advisable to have a carbon monoxide detector nearby when operating any generator to ensure safe use.

By converting your inverter generator to propane, you enhance its efficiency and environmental friendliness and gain a versatile power solution that adapts to various needs. As we wrap up, we’ll summarize the benefits of transitioning from traditional generators to inverter technology and explore resources for maintaining your setup.

Conclusion

As we wrap up our exploration of transitioning from traditional generators to inverter technology, it’s clear that the benefits are substantial and multifaceted. Inverter technology offers cleaner and more efficient energy conversion, which is not only beneficial for reducing fuel consumption but also crucial for minimizing environmental impact. This transition supports a more sustainable and eco-friendly approach to power generation, aligning with global efforts to reduce carbon emissions and promote renewable energy sources.

Inverter generators stand out for their ability to provide stable power, making them ideal for sensitive electronics and essential appliances. Their adaptability to varying power demands ensures that energy is used efficiently, reducing waste and enhancing the longevity of both the generator and connected devices.

For those considering this transition, exploring resources and updates is vital to maintaining and expanding your energy setup. Renewable Energy Nexus offers a wealth of information and products aimed at supporting eco-friendly power solutions. Their range of solar panels, for instance, provides an excellent opportunity to integrate renewable energy into your system, further reducing reliance on fossil fuels and lowering overall energy costs. You can explore their offerings here.

Imagine a future where your power needs are met sustainably and efficiently, with minimal environmental impact. Adopting inverter technology and integrating renewable solutions not only promotes a healthier planet but also provides peace of mind through reliable and clean energy. As you consider this transition, remember that each step towards a more sustainable power system is a step towards a brighter future.

We encourage you to explore further updates and resources to maintain and expand your setup. By staying informed and proactive, you can optimize your energy solutions, ensuring they meet both current and future needs. Embrace the change and take action today for a sustainable tomorrow.

FAQs on Generator to Inverter Transition

1. Can you connect a generator to an inverter?

Yes, connecting a generator to an inverter involves linking the generator’s AC output to the inverter’s input. This setup ensures a stable power supply for sensitive electronics, but it’s crucial to follow the manufacturer’s instructions for safe connections.

2. Is it better to have an inverter on a generator?

Having an inverter on a generator enhances versatility, allowing it to power more appliances. Inverter generators are quieter, lighter, and provide clean power, making them ideal for sensitive electronics.

3. What are the benefits of converting a generator to an inverter?

Converting a generator to an inverter improves efficiency and reduces emissions. It allows for more stable power output, which is crucial for delicate devices, and it supports a more eco-friendly energy solution.

4. How do inverter modules enhance generator efficiency?

Inverter modules convert DC to AC with high efficiency, reducing energy loss and operational expenses. They offer scalability and flexibility, making them ideal for expanding power systems sustainably.

5. What are the advantages of integrating batteries into a generator setup?

Integrating batteries provides consistent power during outages and peak demands. This setup, especially when combined with solar panels, enhances energy reliability and reduces reliance on fossil fuels.