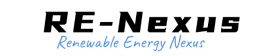

Introduction to Battery Series vs Parallel

When you think about battery configurations, the terms ‘series’ and ‘parallel’ often come up. But what do they mean, and why are they important? Imagine your battery setup as a team working toward a common goal. In a series configuration, batteries are linked end-to-end, much like a relay race where each runner passes the baton to the next. This setup increases the total voltage across the batteries while maintaining the same capacity, or amp-hour (Ah), as a single unit. For instance, connecting two 12V batteries in series results in a total voltage of 24V, but the capacity remains unchanged at 30Ah (Battery University).

Conversely, in a parallel configuration, batteries are connected side-by-side, akin to runners starting a race simultaneously. This enhances the total capacity by summing the capacities of each battery, while the voltage remains constant. So, if you connect the same 12V batteries in parallel, you’ll maintain a 12V voltage but double the capacity to 60Ah (Vatrer Power).

Understanding these configurations is crucial for optimizing power systems. The choice between series and parallel affects not only the voltage and capacity but also the efficiency and safety of your battery system. For applications requiring higher voltage, such as electric vehicles or power tools, series connections are ideal. Meanwhile, parallel connections are perfect for extending battery life and ensuring a longer runtime, making them suitable for RVs, boats, and backup power systems.

By grasping the differences between battery in series vs parallel configurations, you can make informed decisions that enhance the performance and longevity of your power systems. This knowledge is invaluable, whether you’re setting up solar panels, powering an electric vehicle, or simply ensuring your devices run smoothly.

Understanding the Core Concepts of Series and Parallel Circuits

When it comes to configuring batteries, understanding the fundamental differences between series and parallel circuits is essential. These configurations determine how voltage and capacity are managed within a power system, influencing performance and efficiency.

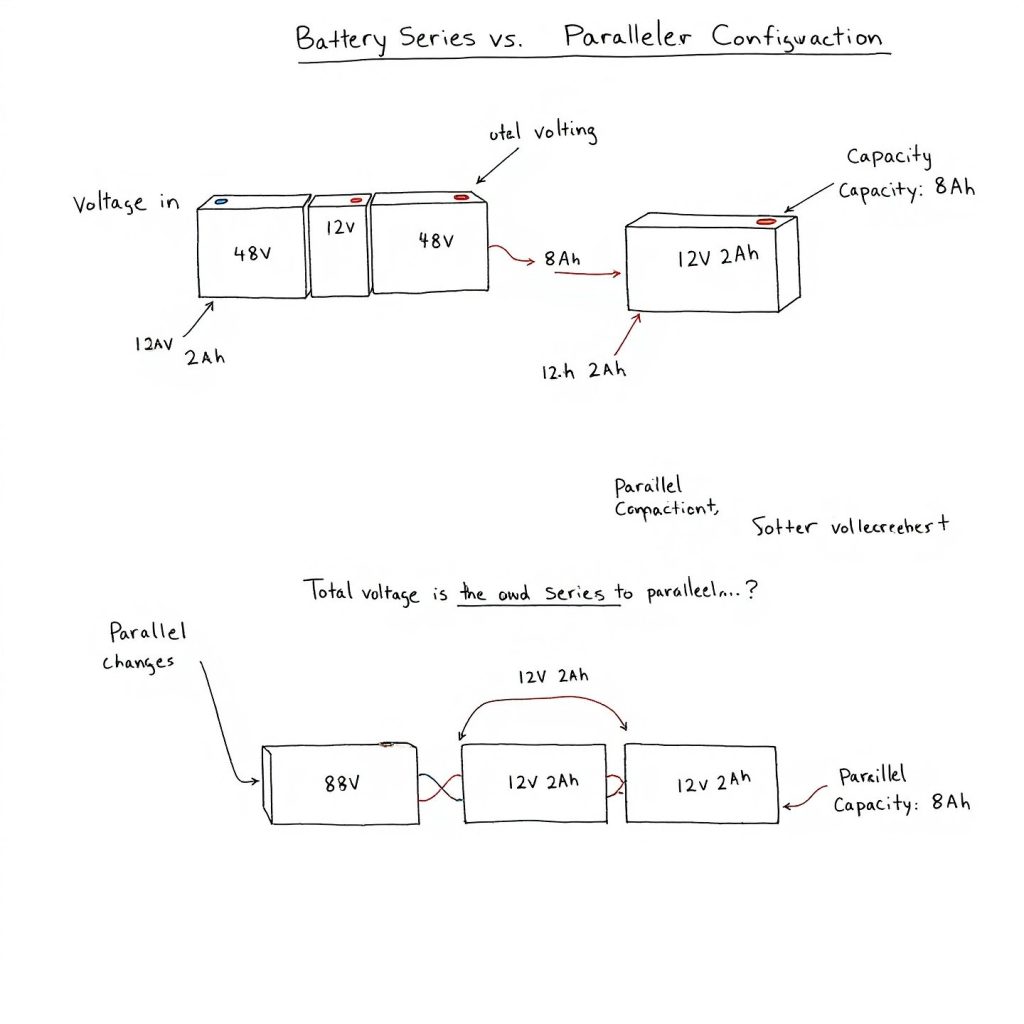

Series Circuits: Increasing Voltage

In a series circuit, batteries are connected end-to-end, with the positive terminal of one battery linked to the negative terminal of the next. This setup increases the total voltage while keeping the capacity constant. For example, if you connect two 12V batteries in series, the resulting voltage is 24V, but the amp-hour (Ah) capacity remains the same as a single battery. This configuration is ideal for applications requiring higher voltage, such as inverters or electric vehicles (RES Supply).

Parallel Circuits: Boosting Capacity

Conversely, parallel circuits connect batteries by linking all positive terminals together and all negative terminals together. This configuration maintains the same voltage as a single battery but increases the total capacity by adding up the capacities of each battery. For instance, two 12V batteries connected in parallel will still provide 12V, but the capacity doubles, extending the runtime for devices like RVs and backup power systems (LithiumHub).

Pros and Cons: Weighing Your Options

Each configuration has its advantages and disadvantages. Series circuits are advantageous for achieving higher voltage, which is necessary for powering high-demand applications. However, they do not increase capacity, which means the runtime remains unchanged. On the other hand, parallel circuits enhance capacity, allowing for longer operational periods, but they require thicker cables and may experience higher current draw, leading to potential voltage drops.

Ultimately, the decision between series vs parallel circuits depends on your specific power needs. If higher voltage is your priority, series connections are the way to go. If you need extended runtime, parallel configurations are more suitable. By understanding these core concepts, you can optimize your battery setup for maximum efficiency and performance.

Examining Voltage and Current in Different Configurations

When configuring batteries in series or parallel, understanding how voltage and current behave is crucial for optimizing your power system. Let’s delve into these behaviors and see how they influence the overall performance of your battery setup.

Voltage in Battery Series vs Parallel

In a series configuration, the voltage of each battery adds up, resulting in a higher total voltage. For instance, connecting three 12V batteries in series produces a total voltage of 36V. This is because the voltage across each battery is cumulative. This setup is beneficial for applications that require a higher voltage to operate efficiently, such as electric vehicles or certain power tools (Wikipedia).

Conversely, in a parallel configuration, all batteries share the same voltage as a single battery. If you connect three 12V batteries in parallel, the total voltage remains 12V. This configuration is ideal for applications that benefit from increased capacity rather than higher voltage, such as in backup power systems or devices that require extended runtime (All About Circuits).

Current Distribution in Series vs Parallel Batteries

Current behaves differently in series and parallel configurations. In a series circuit, the current remains constant throughout the circuit. This means that each battery in the series must handle the same amount of current. This uniformity is beneficial for ensuring that each component of the circuit operates at the same current level, which can be crucial for certain applications (Wikipedia).

In contrast, a parallel circuit allows each battery to contribute to the total current independently. The total current in a parallel configuration is the sum of the currents through each branch. This setup can significantly increase the total current capacity, making it suitable for applications requiring a higher current output, such as powering large inverters or heavy-duty equipment (All About Circuits).

| Configuration | Voltage Output | Amperage (Current) | Total Watt-Hour Capacity |

|---|---|---|---|

| Series | Sum of individual voltages | Constant across all batteries | Same as a single battery |

| Parallel | Same as a single battery | Sum of individual currents | Sum of individual capacities |

Understanding these differences in voltage and current distribution is vital for tailoring your battery setup to meet specific power requirements. Whether you need the increased voltage of a series configuration or the enhanced capacity of a parallel setup, knowing how these elements interact will help you make informed decisions for your energy solutions.

Learning the Essentials of Wiring Batteries in Series

When you need to increase the voltage of your power system, wiring batteries in series is a practical solution. Imagine needing to power an electric vehicle or a solar energy system—these applications often require higher voltages that a single battery cannot provide. By connecting batteries in series, you can achieve the desired voltage without altering the capacity. Let’s explore the step-by-step process of wiring batteries in series, ensuring you do it safely and effectively.

Step-by-Step Guide to Series Wiring

- Prepare Your Batteries: Ensure that all batteries are of the same type, voltage, and capacity. Mixing different types or capacities can lead to imbalances and potential failures. For instance, when using lithium-ion batteries, uniformity is key to maintaining system stability (Ufine Battery).

- Connect the Batteries: Start by connecting the positive terminal of the first battery to the negative terminal of the next. Continue this pattern for each subsequent battery. The last battery’s negative terminal and the first battery’s positive terminal will serve as the system’s output terminals.

- Check Voltage: After connecting the batteries, use a multimeter to verify the total voltage. For example, if you connect three 3.7V batteries in series, the expected voltage should be 11.1V. This step ensures that the system is balanced and functioning correctly (Higher Wire).

Safety Tips and Considerations

Wiring batteries in series requires attention to detail and adherence to safety guidelines. Here are some tips to ensure a safe setup:

- Use Correct Polarity: Always double-check the polarity before making connections. Incorrect polarity can lead to short circuits and damage to the batteries.

- Implement a Battery Management System (BMS): A BMS is crucial for monitoring and balancing the charge across the batteries, preventing overcharging and undercharging issues.

- Ensure Proper Insulation and Ventilation: Insulate connections to prevent accidental shorts, and ensure your workspace is well-ventilated to avoid overheating.

- Regular Inspections: Routinely check the battery connections and voltage levels to maintain optimal performance and safety.

By following these steps and safety precautions, you can effectively wire batteries in series, achieving the necessary voltage for your projects while minimizing risks. This foundational knowledge sets the stage for exploring parallel configurations, where the focus shifts to increasing capacity.

Exploring the Best Practices for Parallel Connections

When it comes to enhancing the capacity of your battery system, wiring batteries in parallel is the way to go. This configuration allows you to increase the total capacity while maintaining the same voltage, making it ideal for applications that demand extended runtime, such as solar power systems and backup energy solutions. But how do you ensure that your parallel battery connections are effective and safe? Let’s break it down into manageable steps.

Step-by-Step Guide to Parallel Wiring

- Check Battery Compatibility: Before wiring, ensure all batteries are of the same type, voltage, and capacity. This uniformity is crucial to prevent imbalances that could lead to inefficient operation or even damage.

- Measure Initial Voltage: Use a multimeter to measure the voltage of each battery. They should all have approximately the same voltage. If not, charge or discharge them to equalize their voltages before proceeding (Cell Saviors).

- Connect Terminals: Link all positive terminals together and all negative terminals together. This setup will increase the total capacity while keeping the voltage constant (Victron Energy).

Cable Gauge Considerations

Choosing the right cable gauge is essential for minimizing resistance and ensuring efficient power distribution. The cables should be thick enough to handle the increased current without overheating. Refer to an electrical cable gauge chart to select the appropriate size for your setup.

Balancing Current Draw

Properly balanced current draw across all batteries is vital for extending their lifespan and maintaining system efficiency. Here are some tips:

- Use Busbars: Implementing busbars can help distribute the current evenly across all batteries, reducing the risk of overloading any single unit.

- Regular Monitoring: Periodically check the voltage and temperature of each battery. Imbalances can often be detected early through these regular inspections.

By following these best practices, your parallel battery connections will not only increase capacity but also ensure reliability and longevity. This understanding sets the stage for exploring more complex configurations, such as combining series and parallel setups for optimal performance.

Optimizing 12V Battery Setups for Reliable Power

When configuring 12V batteries, understanding the differences between series and parallel setups is crucial for achieving stable power outputs. Whether you’re powering an RV, a boat, or a solar energy system, the way you connect your batteries can significantly impact performance and efficiency. Let’s explore how to optimize these configurations for reliable power delivery.

12V Batteries in Series: Elevating Voltage

Connecting 12V batteries in series increases the total voltage while maintaining the same capacity. This is particularly useful for applications requiring higher voltage levels, such as inverters or electric vehicles. For example, linking two 12V batteries in series results in a 24V system, ideal for devices that need more voltage to function effectively (Power Sonic).

To wire 12V batteries in series, connect the positive terminal of the first battery to the negative terminal of the second. The remaining positive and negative terminals will be your output terminals, providing the combined voltage of the connected batteries. It’s essential to ensure that all batteries used are of the same voltage and capacity to avoid imbalances and potential damage.

12V Batteries in Parallel: Boosting Capacity

In contrast, a parallel configuration keeps the voltage level at 12V but increases the total capacity. This setup is advantageous for applications requiring extended runtime, such as backup power systems or solar energy storage. By connecting the positive terminals of all batteries together and the negative terminals together, you effectively increase the amp-hour capacity, allowing your system to power devices for longer periods (BatteryStuff).

Using 12V batteries in parallel requires careful attention to cable gauge to handle the increased current without overheating. Additionally, balancing the current draw across all batteries is vital to ensure each unit discharges and recharges evenly, thereby extending the overall lifespan of your battery bank.

Common Usage Scenarios and Considerations

Choosing between series and parallel configurations depends on your specific power needs. For instance, if you’re setting up a solar power system that requires a 24V input, series wiring is necessary. On the other hand, if you’re looking to maximize storage capacity for a 12V system, such as in an RV or boat, a parallel setup is more suitable.

Voltage regulation and charge distribution are also critical factors to consider. Implementing a battery management system (BMS) can help monitor and balance the charge across all batteries, preventing overcharging and undercharging issues. Regular inspections and maintenance are equally important to ensure your system operates efficiently and safely.

By understanding and applying these principles, you can optimize your 12V battery configuration for reliable and efficient power delivery, tailored to meet the demands of your specific application.

Managing Capacity and Current with Multi-Battery Banks

When you’re looking to power large systems or ensure extended energy supply, combining multiple batteries into a bank can be the solution. But how exactly does this setup affect total capacity and current draw? And what strategies can you employ to structure these battery banks efficiently? Let’s dive into the intricacies of multi-battery bank configurations.

Understanding Capacity and Current in Multi-Battery Configurations

Imagine you have a set of batteries, and you’re deciding whether to connect them in series or parallel. Each configuration has unique impacts on the system’s performance. For instance, when you connect 2 batteries in series, you increase the voltage while keeping the capacity the same. This setup is ideal for applications requiring higher voltage, such as certain power tools or electric vehicles.

On the other hand, connecting batteries in parallel increases the total capacity, which is crucial for applications needing longer runtime, like solar power systems. For example, if you connect two 12V batteries in parallel, the voltage remains 12V, but the capacity doubles, allowing for extended use.

Strategies for Efficient Multi-Battery Bank Configuration

To efficiently manage a multi-battery bank, consider the following strategies:

- Proper Sizing: Ensure your battery bank is sized correctly for your energy needs. This involves calculating your total power requirements and matching them with the appropriate number of batteries (Renogy).

- Balanced Connections: Use busbars to distribute current evenly across all batteries. This helps prevent any single battery from being overworked, which can lead to premature failure.

- Regular Monitoring: Implement a battery management system (BMS) to monitor the state of charge and discharge cycles. This system helps maintain balance and prevents issues like overcharging or deep discharging, which can shorten battery lifespan.

- Flexibility in Design: Consider a modular approach where batteries can be easily added or removed based on changing power needs. This flexibility can be crucial for adapting to different energy demands over time.

Practical Applications and Considerations

Multi-battery banks are commonly used in solar energy systems, RVs, and backup power solutions. In these applications, the choice between series and parallel configurations—or a combination of both—depends on specific power requirements. For instance, a solar power system might use a combination of series and parallel connections to achieve both the desired voltage and capacity.

Another key consideration is the environment where the batteries are used. Extreme temperatures can affect battery performance and lifespan. Therefore, ensure your battery bank is installed in a temperature-controlled environment to optimize efficiency and longevity.

By understanding the effects of combining multiple batteries and employing strategic configurations, you can effectively manage capacity and current in your battery bank. This approach not only enhances performance but also ensures the longevity of your energy storage system, paving the way for a more reliable and efficient power solution.

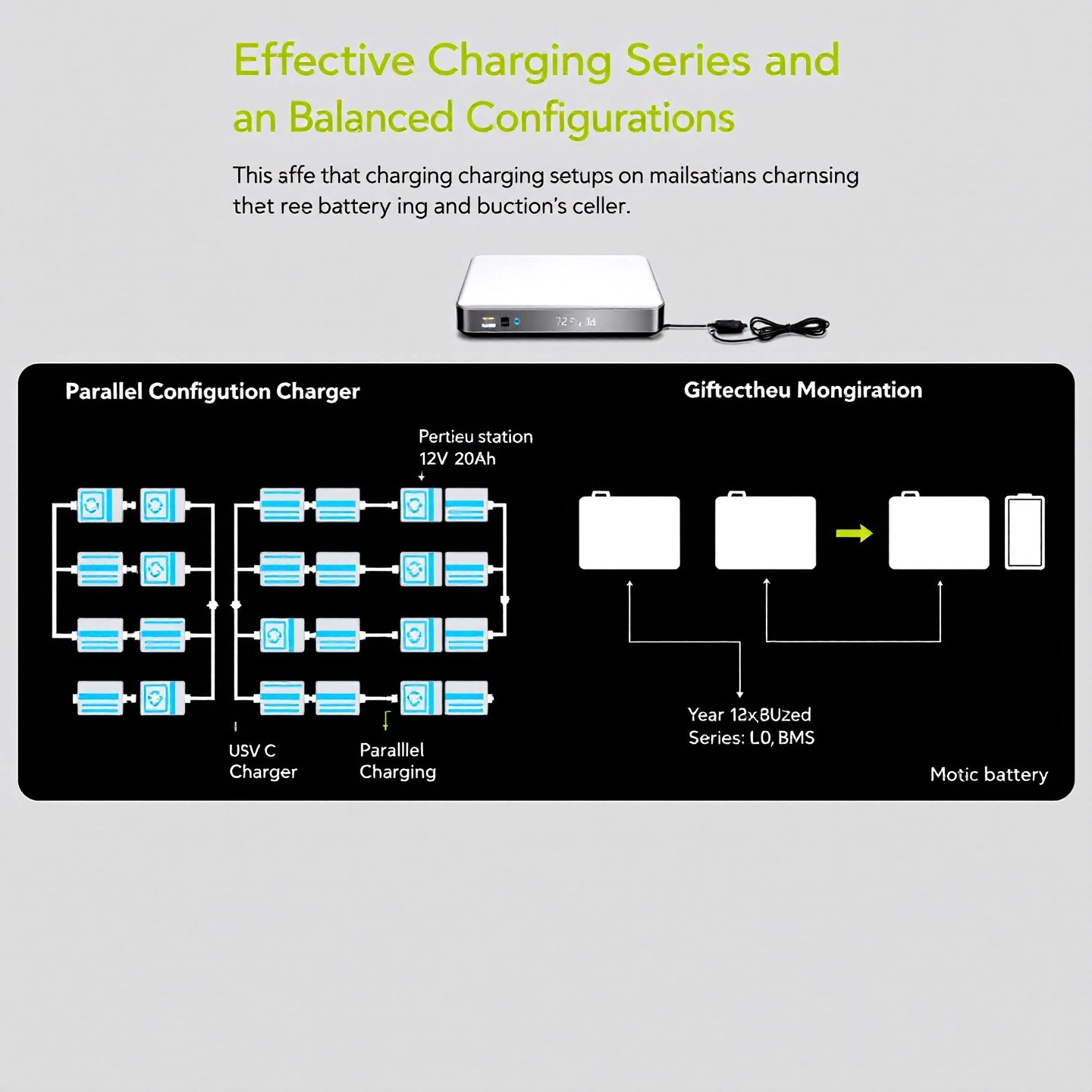

Implementing Effective Charging Methods for Various Arrangements

Charging batteries effectively is crucial for maintaining their performance and longevity, especially when dealing with different configurations like series and parallel. Understanding the nuances of each setup can help prevent overcharging and ensure your batteries are always ready for use. Let’s explore the best practices for charging batteries in series vs parallel, and how to choose the right battery charging methods for your setup.

Charging Batteries in Series

When charging batteries connected in series, the objective is to increase the voltage output while maintaining the same current capacity. This configuration requires a charger with a voltage output equal to the total voltage of the series-connected batteries. For instance, if you have two 12V batteries in series, a 24V charger is necessary to charge the system efficiently. It’s crucial to ensure that the charger is compatible with the combined voltage to avoid undercharging or overcharging (Impact Battery).

One of the main challenges with series charging is ensuring each battery receives an equal charge. This can be mitigated by using a smart charger with individual battery monitoring capabilities. Such chargers can detect and adjust the charging process to balance the charge across all batteries, preventing issues like voltage imbalance and extending the batteries’ lifespan.

Charging Batteries in Parallel

In a parallel configuration, all batteries share the same voltage, but the total capacity increases. Here, a single charger with a voltage output matching the individual battery voltage is used. For example, charging a set of parallel-connected 12V batteries requires a 12V charger. The parallel setup allows for a single charger to distribute current across all batteries, simplifying the charging process (Battery Tender).

However, to ensure that each battery in a parallel setup charges evenly, it’s essential to use high-quality connecting cables and ensure all connections are secure. Additionally, regular monitoring of each battery’s voltage and temperature can help identify any imbalances early on, allowing for timely adjustments.

Preventing Overcharging and Ensuring Safety

Overcharging is a common concern with both series and parallel configurations, as it can lead to battery damage and reduced lifespan. To prevent this, consider the following safety tips:

- Use Smart Chargers: These chargers automatically adjust the charging current and cut off when the battery is fully charged.

- Monitor Charging Cycles: Regularly check the state of charge and disconnect the charger once the batteries are fully charged.

- Incorporate Battery Management Systems (BMS): A BMS can monitor and balance the charge across all batteries, providing an additional layer of protection against overcharging.

By following these best practices for charging batteries in series vs parallel, you can optimize your battery setup for maximum efficiency and longevity. These methods not only enhance performance but also ensure the safety and reliability of your power systems.

Maintaining Safety and Longevity in Your Battery System

When it comes to battery systems, safety and longevity are paramount. Whether you have batteries connected in series or parallel, understanding the nuances of each configuration can help you maintain a safe and efficient power system. So, how can you ensure your battery setup remains reliable over time?

Load Balancing: The Key to Efficient Operation

Effective load balancing is crucial in both series and parallel configurations. In a series setup, the current flowing through each battery remains constant, which means each battery must be capable of handling the same load. Any imbalance can lead to overheating or reduced efficiency. In parallel configurations, the current is divided among the batteries, which can lead to uneven discharge rates if not properly managed. To mitigate these risks, consider using a Battery Management System (BMS) to monitor and balance the load across all batteries, ensuring optimal performance (IBCI Power).

Regular Inspections: Detecting Issues Early

Frequent inspections are essential for maintaining battery system safety. Look for signs of wear, such as corrosion on terminals, bulging, or leaks. These issues can indicate underlying problems that could compromise the safety and efficiency of your system. Regularly checking voltage levels and ensuring connections are secure can help prevent potential failures. By catching these signs early, you can address them before they escalate into major issues (Bioenno Power).

Maintenance Schedules: Extending Battery Life

Establishing a maintenance schedule is a proactive approach to ensure your battery system remains in top condition. This includes cleaning terminals to prevent corrosion, checking electrolyte levels in lead-acid batteries, and ensuring that all connections are tight. Additionally, avoid discharging batteries below 20% of their capacity to prevent damage and extend their lifespan. Consistent maintenance not only enhances performance but also reduces the risk of unexpected failures.

By implementing these battery maintenance tips, you can maintain a safe and efficient battery system. Remember, a well-maintained battery setup not only enhances performance but also ensures the longevity of your power solutions, allowing you to focus on what truly matters—whether it’s powering your home, vehicle, or off-grid system.

Conclusion

When it comes to optimizing your power systems, understanding the configurations of battery series vs parallel can be a game-changer. By mastering these concepts, you can significantly enhance the performance and efficiency of your energy solutions, whether you’re powering a small device or a large-scale system. So, what are the key takeaways from exploring these configurations?

First, consider the specific needs of your application. Are you looking to increase voltage or boost capacity? Series configurations are ideal for applications requiring higher voltage, such as electric vehicles or high-power tools. On the other hand, parallel configurations excel in extending capacity, making them perfect for systems that demand longer runtime, like solar energy storage or backup power solutions.

Next, it’s crucial to ensure compatibility and balance within your battery system. This involves using batteries of the same type, voltage, and capacity to prevent imbalances that could lead to inefficiency or failure. Implementing a Battery Management System (BMS) can further optimize performance by monitoring and balancing charge and discharge cycles across the batteries.

Moreover, regular maintenance and monitoring are essential to prolong battery life and maintain safety. By establishing a routine for inspections and upkeep, you can prevent issues before they escalate, ensuring your battery system operates smoothly and reliably.

As we look to the future of battery technology, advancements continue to offer more efficient and sustainable solutions. By staying informed and applying these insights, you can harness the full potential of your battery systems, contributing to a more sustainable and energy-efficient future.

We encourage you to explore further resources and stay updated on the latest innovations in battery technology. Whether you’re a hobbyist or a professional, understanding how to optimize battery performance is a valuable skill that can enhance your projects and energy solutions.

Battery Series vs Parallel: Frequently Asked Questions

1. Is it better to run batteries in series or parallel?

Running batteries in series increases voltage, ideal for high-power applications like electric vehicles. Parallel setups boost capacity, offering longer runtimes, suitable for backup systems or solar storage.

2. How can you tell if batteries are in series or parallel?

In series, batteries are connected end-to-end, increasing voltage. In parallel, they’re connected side-by-side, maintaining voltage but increasing capacity. Check terminal connections to differentiate.

3. What are the advantages of using batteries in parallel?

Parallel configurations increase total capacity, allowing for longer device operation. This setup is beneficial for systems needing extended runtime, such as RVs and solar power storage.

4. How do you safely charge batteries in series?

Use a charger with voltage matching the total series voltage. Smart chargers help balance charge across batteries, preventing overcharging and ensuring even distribution.

5. What precautions should be taken for battery maintenance?

Regularly inspect for corrosion, secure connections, and use a Battery Management System (BMS) to monitor load and balance. Avoid deep discharging to extend battery life.